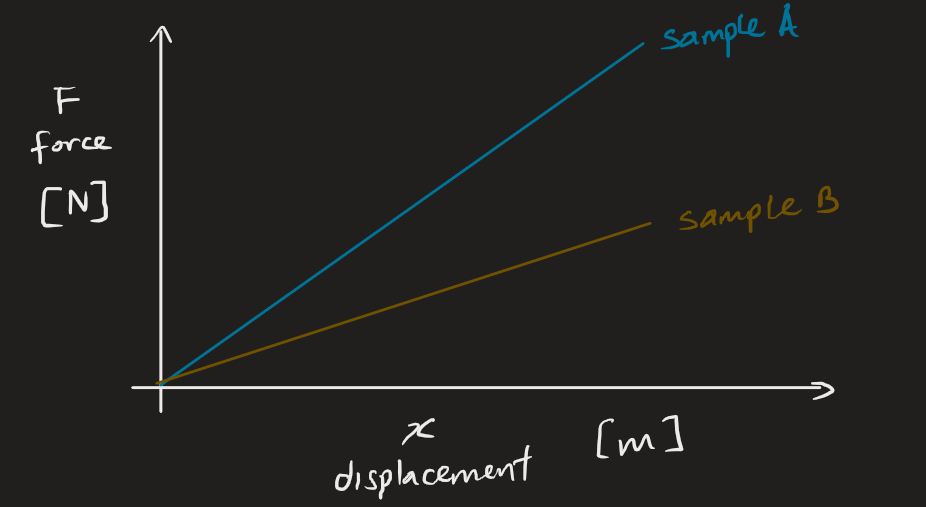

We test materials based on their physical properties, the most important of which are stress and strain. We’re interested in material properties, but Hooke’s law, is sample-size dependent. If two samples are exactly the same material but are different sizes, the larger material appears to be stronger with a higher spring constant. We aim to normalise the behaviour and make measurement sample-size independent.

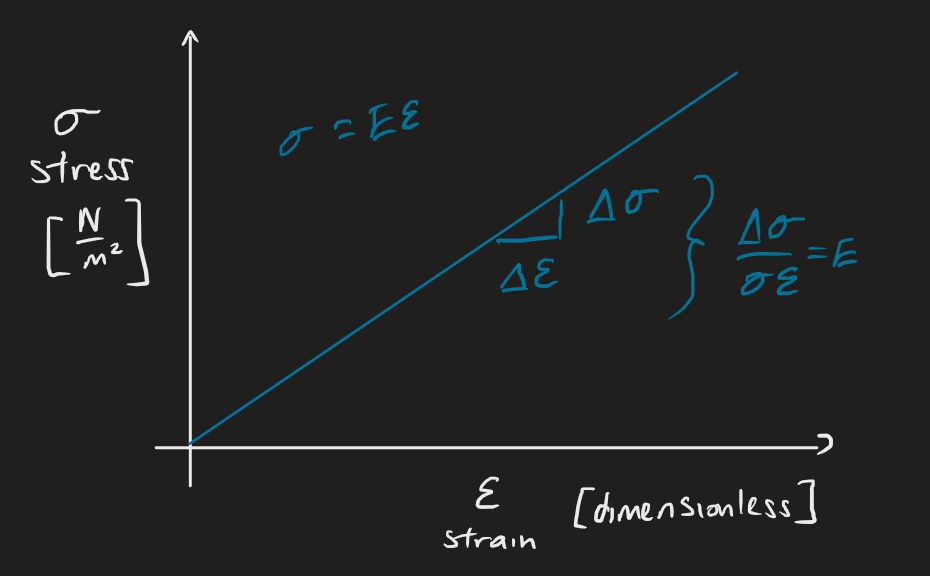

We measure stress () in pascals (Pa), defined as the applied force divided by the initial cross-sectional area. Strain () is dimensionless. The slope of a plotted stress versus strain curve is the Young’s modulus, . Since we test ceramics differently than metals, we use a different formula for a three-point bend:

Graphically

The force-displacement expression of Hooke’s law isn’t very useful for us if we want to figure out material properties. For example, if we have two samples with differing dimensions, we have a different spring constant :

Using stress and strain instead.

Using stress and strain instead.

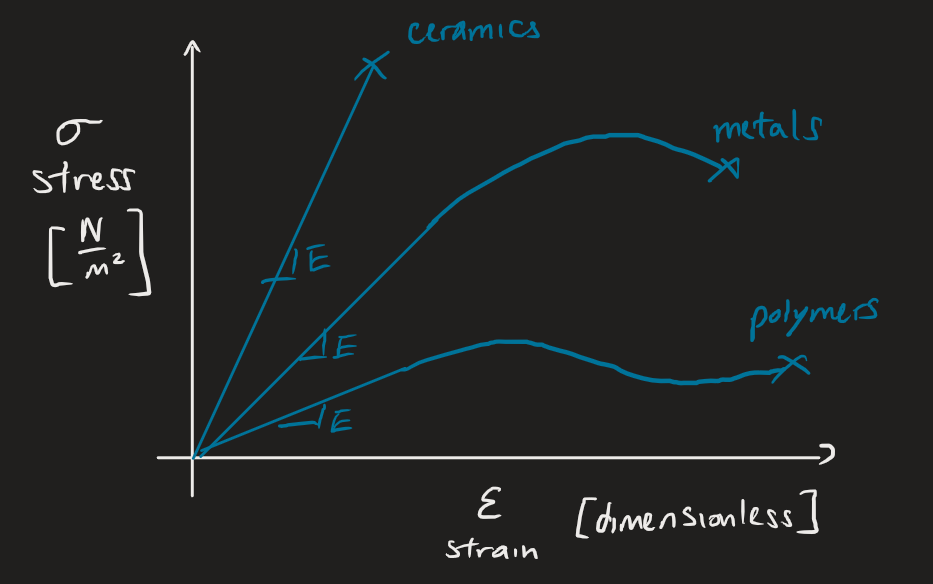

Different materials behave differently.

Different materials behave differently.